THERMOCHEMICAL CONVERSION TECHNOLOGY

At EnviroMaster, we want asbestos waste annihilation, not accumulation.

Even though asbestos has been banned and is being removed from our built environment, does not mean it is gone.

Every year, millions of tonnes of hazardous asbestos waste is stored, buried in landfill.

Contaminating the earth from which we eat, and passing the problem from one generation to the next.

But as the world turns its back on landfill, and pushes toward a more circular economy, EnviroMaster’s patented Thermochemical Conversion Technology (TCCT) provides an opportunity to set a worldwide precedent for eradicating asbestos waste and obliterating asbestos’ lethal legacy.

Click for more information:

Once marketed as a “magic mineral,” asbestos is now an infamous public health menace which has left a lethal legacy.

Long considered one of the most versatile minerals because of its flexibility, tensile strength, insulating properties (heat and electricity), chemical inertness and affordability, asbestos was used in over 3,000 different applications worldwide.

Australia was one of the highest per capita asbestos users and approximately one third of all homes in Australia contain asbestos products. New Zealand’s use was lower than many industrialised countries until the 1970s-1980s when per capita use exceeded that of the USA and the UK – an estimated 40,000 commercial and residential properties in Christchurch alone contain asbestos.

Asbestos exposure, however, causes a number of serious diseases including mesothelioma, a highly aggressive cancer; asbestosis, a chronic lung disease; along with cancers of the lung, larynx and ovary; and pleural disorders such as pleural plaques and thickening. It has also been linked to cancers of the stomach, pharynx and colon.

Australia has one of the highest recorded rates of mesothelioma and other asbestos-related diseases in the world due to the country’s past heavy use. New Zealand falls marginally behind, with upwards of 20,000 people listed on the national Asbestos Exposure Register.

Smaller nations are not immune. A 1994 study linked New Caledonia’s high rate of cancer of the pleura – the lining of the lung – with the use of asbestos in the construction of traditional Melanesian huts. Since then, the huts have been destroyed, but the problem persists. Whilst the 2017 State of Asbestos in the Pacific report found more than 187,000 square metres of confirmed non-residential asbestos across 11 Pacific Island countries, 78% of which was classified as either high or moderate risk.

Currently in Australia, as well as throughout much of the developed world, asbestos waste can only legally be disposed of at licensed landfills. However, this method does not alter fibre structure, therefore does not render the waste intrinsically safe for human health and the environment. Furthermore, asbestos waste is typically a low-density waste and thus, occupies an inordinate volume of landfill space.

Landfilling merely provides a storage solution that requires long term management to minimise risk of deterioration and interference, the financial cost of which is mostly the responsibility of State and Territory Governments and Local Councils. However, the environmental and human health impacts will be borne by current and future generations.

Thermochemical Conversion Technology or TCCT utilises size reduction of wastes, application of fluxing solution and heat to treat asbestos waste that would otherwise be landfilled.

The TCCT process results in an inert, non-hazardous end treated product that can be used in a variety of non-structural construction applications.

This exciting patented technology will set a worldwide precedent for eradicating asbestos waste.

EnviroMaster, as the exclusive Australasian licensee of TCCT, is focused on asbestos destruction, not asbestos disposal:

- From harmful to harmless

TCCT results in the permanent and irreversible destruction of asbestos, converting it into a non-hazardous, inert product. - Reduces waste to landfill

TCCT diverts asbestos, and its containment material, away from landfill. Landfills are at capacity, so TCCT frees up valuable realestate. - Reduces waste volume

TCCT results in waste minimisation – utilising this technology significantly reduces both the mass (average 33%) and volume (average 73%) of asbestos waste. - Utilises plastics for fuel

TCCT utilises plastic waste including polyethylene and polypropylene, which would otherwise be landfilled, to generate fuel to run processing. - Commercially viable

With the rising cost of asbestos disposal, TCCT provides a commercially viable alternative to landfill. - Technologically mature

With a 25-year plus development history, TCCT it the most mature technology available worldwide for the treatment of asbestos. Granted a National Operating Permit by the U.S. EPA.

TCCT utilises a thermochemical conversion process, which includes size reduction of wastes, application of fluxing solution to the waste and heating of the waste to produce an inert, non-hazardous end (treated) product.

In the TCCT process, asbestos waste is processed first via a slow-speed, rip-shear shredding system where the material is broken down to a uniform particle size.

From the shredding system, the material is fed via a conveyor system to a rotary hearth.

Before entering the rotary hearth, a fluxing solution is introduced into the asbestos waste stream. This fluxing solution uses sodium borate, commonly known as borax, a product used domestically as a multipurpose household cleaner, stain remover and deodoriser.

The rotary hearth is a continuous feed furnace with a variable residence time. Asbestos waste is heated to a temperature of approximately 1230°C (2250°F) during hearth rotation.

In EnviroMaster’s TCCT process, plastic waste is used as fuel to supplement furnace energy requirements (note, alternative fuel sources may be suitable where plastic is not appropriate in specific markets). Most non-chlorinated plastics contain energy equivalent to that of diesel fuel. The high energy density of plastics means that as little as 7% plastic to asbestos waste is sufficient to supply substantially all of the thermal energy requirements for the TCCT process.

Asbestos destruction efficiency of 100% is achieved in 20 minutes of processing.

The output of the furnace (the end treated product) is a non-hazardous, inert aggregate which can be used in many non-structural construction applications.

Independent testing of the end treated product highlighted potential civil engineering applications including earth and embankment fills, aggregate for road base, granular drains and filters, and aggregate for weaker concrete and flowable fills.

Off-gases of the TCCT process are routed through a secondary thermal oxidizer, a venturi, then three packed bed scrubbers installed in series, a demister, reheater, and bag house before being discharged via a stack. This pollution abatement system ensures the facility will not discharge any asbestos fibres and will meet and/or surpass all relevant and appropriate regulatory requirements.

For more information on EnviroMaster’s TCCT process, download our Concept Facility Process Map.

Many asbestos minerals are part of the serpentine group of hydrated silicates and the asbestiform minerals have a structural resemblance to the serpentine minerals. Although the serpentine minerals are physically fibrous, they are layered silicates.

Serpentine minerals will expel structural water (hydroxyl groups) at between 700 and 800°C. However, this reaction is slow even at much higher temperatures. This slow reaction coupled with the superior insulating properties of the fibrous forms (asbestos) make them particularly difficult to destroy thermally. Without the presence of fluxing agents, conversion can take nearly two hours even at temperatures as high as 1200°C in particles as small as five (5) centimetres in diameter. Larger particles take longer due to slow heat transfer.

By introducing sodium and boron to asbestos in a concentrated aqueous solution (the fluxing solution), homogenous intimate contact between the cations and asbestos fibres can be attained. The absorbent nature of friable and asbestos cement products assists in the rapid delivery of the fluxing solution to asbestos fibres.

When asbestos waste saturated with the fluxing solution is heated, water evaporates leaving behind sodium and boron. As the temperature continues to rise, the introduced cations become increasingly reactive. At a temperature of approximately 1200°C these cations will react rapidly with other ions in the asbestos fibrils. This reaction takes place quickly resulting in the expulsion of hydroxyl groups, collapse of the hydrated layer and destruction of fibrous morphology.

The result is the formation of new volcanic-type minerals including olivine, wollastonite, diopside, other pyroxenes depending upon the chemistry of the feed, and small amounts of glass where partial melting is initiated. The reactions take place without significant melting of the material (and thus without having to overcome the heat of fusion).

The accelerated destruction of asbestos materials is brought about by the presence of the fluxing agent in the presence of heat. All asbestos waste subjected to nominal operating conditions resulted in end product that was 100% asbestos-free (non-detectable using Transmission Electron Microscopy (TEM), X-ray diffraction and optical analytical methods).

Over its 25-plus year development history, TCCT has successfully destroyed over 1,016 tonnes of asbestos waste.

TCCT was developed and patented by US-based ARI Technologies Inc. (ARI U.S.).

From 1990 until 1994, TCCT evolved through a series of laboratory and engineering scale test phases and scale-ups. These test phases constituted the ‘proof of principle’ for TCCT and prepared the technology for scale-up.

From 1994 to 2007, ARI U.S. conducted several progressively complex and/or larger scale waste treatment projects to improve the performance and efficiency of the technology.

Projects included destruction of asbestos, Polychlorinated Biphenyls (PCB) contaminated materials, toxic metals including lead-based paint, and surrogate radioactive materials. A summary of these waste treatment projects is as follows:

- Validate technology for asbestos destruction pursuant to 40 CFR 61.155 for US Department of Energy, Bechtel Hanford, 1996 – 1997;

- Destroy PCBs and asbestos per TSCA regulations for the Naval Facilities Engineering Command, Engineering Service Centre, 1999;

- Design, build and test a large-scale modular waste treatment system for destruction of asbestos and PCBs for US Department of Defence including an EPA-designed Validation Test Program leading to a National Operating Permit for destruction of PCBs under the Toxic Substances Control Act (TSCA), 1999 – 2002;

- Deploy technology for asbestos destruction and evaluate suitability for immobilisation of toxic metals and surrogate radionuclides for the US Department of Energy, 2000 – 2002;

- Remove, recover and recycle lead from salvaged building materials contaminated with lead- based paint for the US Army Corps of Engineers Construction Research Engineering Laboratory, 2003;

- Design, build and demonstrate a full-scale transportable system for concentrating, recovering and recycling lead from deconstruction materials contaminated with lead-based paint for the US Army Corps of Engineers Construction Research Engineering Laboratory, 2005 – 2007;

- Destroy a wide variety of asbestos waste products over an extended operational period to carefully document emission performance, confirm complete destruction of asbestos and to demonstrate extended process performance and reliability for a Japanese consortium of companies, 2007. For more information on this operation, refer Tacoma, Washington USA (Japanese Consortium) Demonstration Facility.

TCCT has been granted a National Operating Permit by the US Environmental Protection Agency for the thermal destruction of asbestos and PCBs and is recognised as a viable alternative to placement of waste asbestos in landfill within several documents including:

- Reference Document on Best Available Techniques for the Waste Treatment Industries, European Commission (refer EC 2006, section 4.3.3.2), 2006

- Technology Assessment – Asbestos Destruction using ARIs Thermochemical Conversion Technology, British Nuclear Fuels Ltd, 2004

- ARI Technologies Asbestos Destruction, National Energy Technology Laboratory, U.S. Department of Energy, 2002

UK-based ARI Global Technologies Ltd (ARIGT U.K.), a subsidiary of waste management conglomerate Windsor Integrated Services Group, acquired the global rights to the technology in 2014 from ARI U.S.

ARIGT U.K. are currently investigating establishment of TCCT facilities in other jurisdictions including the UK and the Netherlands.

In 2016 the UK’s LLW Repository Ltd. on behalf of the Nuclear Decommissioning Authority shortlisted TCCT as a preferred technology for treatment of low level radioactive waste in its LAW Asbestos and Asbestos Containing Waste Gate B (Preferred Options) Study. The following year, ARIGT U.K. received the European Asbestos Forum’s prestigious International Recognition Award for their “commitment towards the more sustainable management of asbestos waste through its Thermal Chemical Conversion Technology”.

In 2017, ARIGT U.K. secured EnviroMaster as the exclusive territory licensee for the patented technology in the Australasian region.

Since this time, EnviroMaster has been working tirelessly to develop the world’s first, commercial scale TCCT facility, successfully securing over AUD$14 million in funding, through two separate grants, from the Australian Government. This funding is to establish the necessary planning to support the development, operation and future ownership of a trial facility to use TCCT for asbestos waste remediation as an alternative to landfill.

In 2007 a consortium of Japanese companies engaged ARI U.S. to conduct a 10-day operational demonstration of TCCT using a-then existing processing system located in Tacoma, Washington.

Commencing May 2007, ARI U.S. prepared the system for operations, secured the necessary permits and began the task of acquiring asbestos from local abatement contractors.

Two start-up demonstrations took place in July and September during which 6.1 tonnes of waste was processed. These brief operational periods revealed an opportunity to improve the efficiency of the system relating primarily to materials handling equipment and procedures. ARI U.S. made these improvements and moved forward with the demonstration.

At 1800 hours on 10 October 2007, ARI U.S. commenced feeding asbestos waste into the system. The demonstration continued without significant interruption until 1800 hours on 20 October 2007.

During this time, approximately 53 tonnes of asbestos waste was converted into a non-hazardous, asbestos-free aggregate. The asbestos that was processed, totalling 59.1 tonnes of waste including the July and September start-ups, included a wide variety of waste forms containing cement asbestos products and a variety of friable forms including pipe lagging, roofing paper, “popcorn ceiling”, insulating board and spray-on asbestos products, vinyl tile, contaminated soil and all of the other waste products associated with ACM (such as wire, electrical conduit, wood, plastic, glass windows, mastic, nails, etc). Processing rates ranged from 6.8 to 9.07 tonnes/day with minor interruptions for various maintenance activities.

ARI U.S. established a sampling and analytical protocol prior to beginning the demonstration which focused on asbestos analysis and chemical analysis for the treated product, wastewater, product cooling water, HEPA filters, feed material and any other secondary wastes produced by the process. In addition, the analytical procedures included a detailed evaluation of off-gas emissions at three locations in the off-gas processing system.

Results of this demonstration concluded:

- 100% of the treated product was asbestos-free. Analytical procedures included TEM (the most sensitive technology available for identifying asbestos fibres); optical and XRD techniques.

- The permissible exposure limit of 0.1 fibres/cm3 for asbestos workers was never exceeded during any of the operations. Thus, the waste feed process for TCCT is considered a very clean operation.

- Tests conducted on wastewater and HEPA filter fabric samples from the process showed non-detectable concentrations for asbestos.

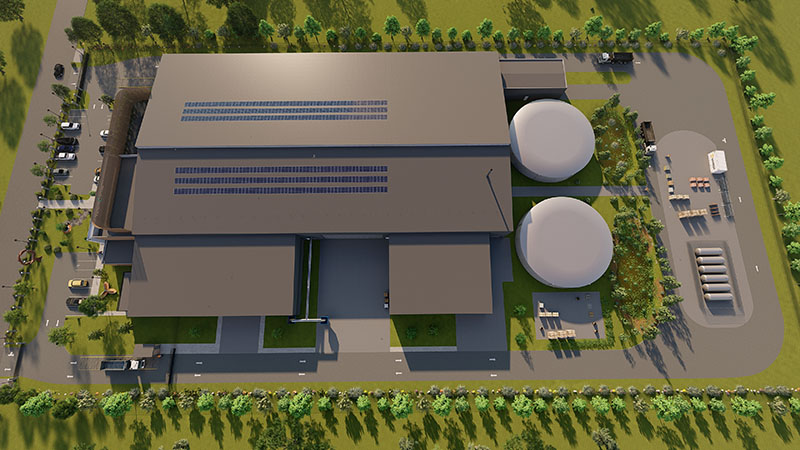

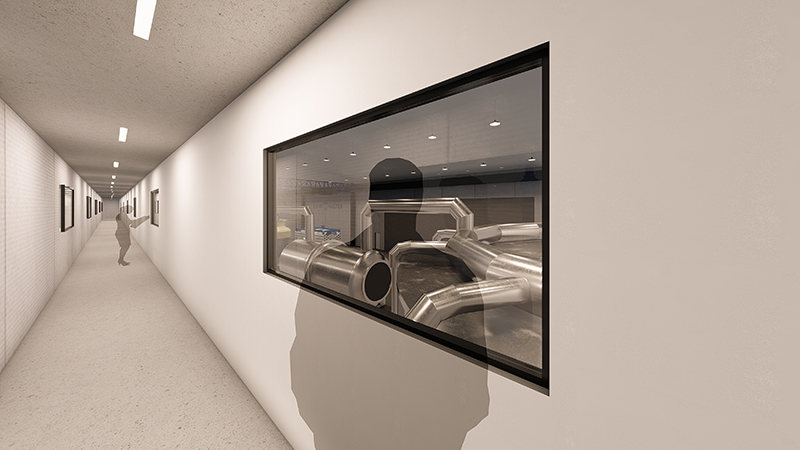

Based on learnings from TCCT’s extensive development history and incorporating technological advancements in hazardous waste processing and emission control, EnviroMaster has developed engineering designs and concept planning for a state-of-the-art, purpose built, commercial scale TCCT asbestos waste processing facility – the first of its kind in the world.

Designed to process a minimum of 100 tonnes of asbestos waste per day, EnviroMaster’s design provides a controlled, integrated facility to receive and process waste, creating a safe working environment for transport staff and facility employees, as well ensuring the safety of surrounding communities. Featuring a main plant, unloading/loading storage sheds, secondary sheds, administration building, and ancillary areas, the entire waste handling system is fully enclosed and maintained at negative pressure to maximise plant and employee health and safety.

EnviroMaster’s work to date provides detailed analysis and mapping from administrative controls through to waste processing and pollution abatement.

Based on EnviroMaster’s system, asbestos is efficiently destructed within 20 minutes of processing, resulting in an inert, non-hazardous end treated product that can be used in a variety of non-structural construction applications.

A fly through of EnviroMaster’s Concept Facility can be viewed here.

In addition, please download our Concept Facility Process Map.

CONCEPT FACILITY ARCHITECTURAL RENDERS

(Please scroll through gallery and click on image to enlarge)